Material Handling and Packaging to Move Battery Components Safely

Battery/EV

Material Handling Solutions From Material Design to Manufacturing

For over 6 years, we have been a trusted battery automation and packaging partner from concept thru manufacturing and beyond. We are commonly called in on OEM and Tier 1 automation packaging or conveyance projects for our engineering expertise and manufacturing experience.

We start with an idea and then create a conceptual part for review with the stakeholders. Because we understand the physical variables involved when determining a solution, we can quickly develop the most efficient manufacturing process and specifications. Our teams continue to reengineer and reinvent products that offer the most economical and unsurpassed features available in the market today.

By exceeding customer requirements, we guarantee future business. Our leading-edge technologies and experience have propelled us from the first EV manufacturers to new manufacturers coming into the industry every day.

Ideally, we like to work with both the OEM and supplier early in the design phase to interact with cross-functional customer teams.

Click to Download Brochure

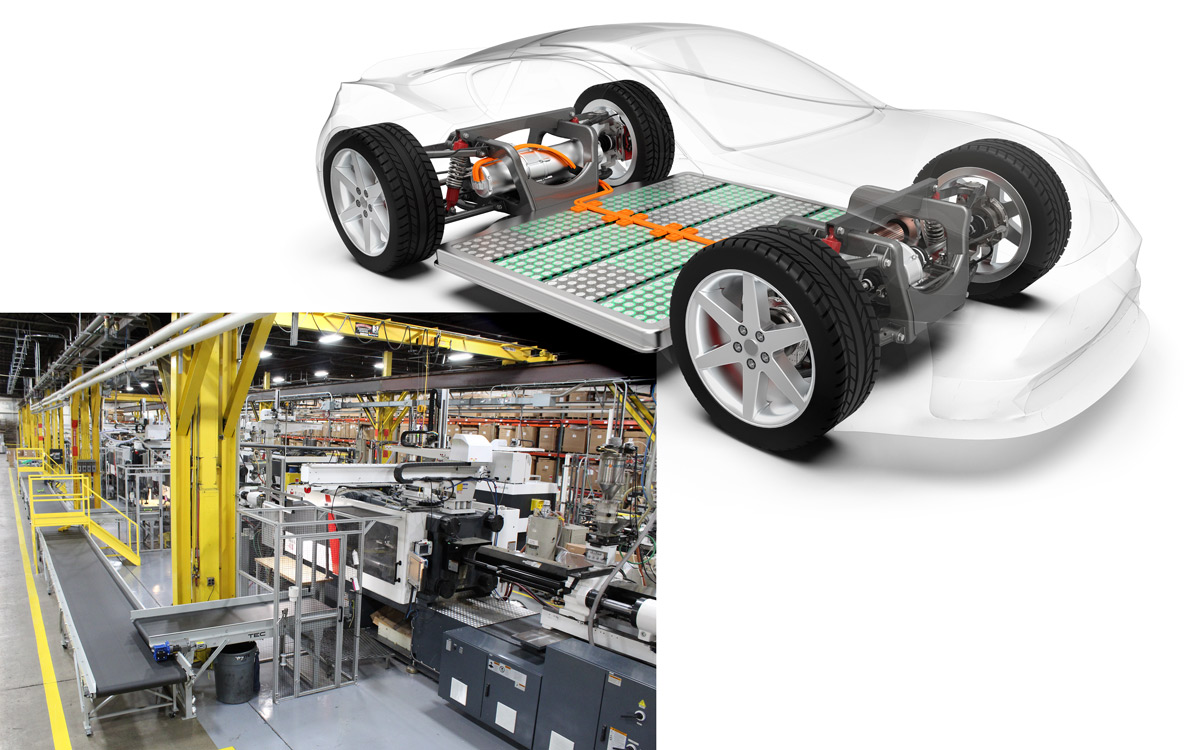

Innovative Material Handling & Component Packaging

We formulate custom materials, design, engineer, rapid prototype and manufacture tray and rack dunnage to move batteries and sensitive components along the automotive supply chain.

- Battery Cans

- Battery Cells

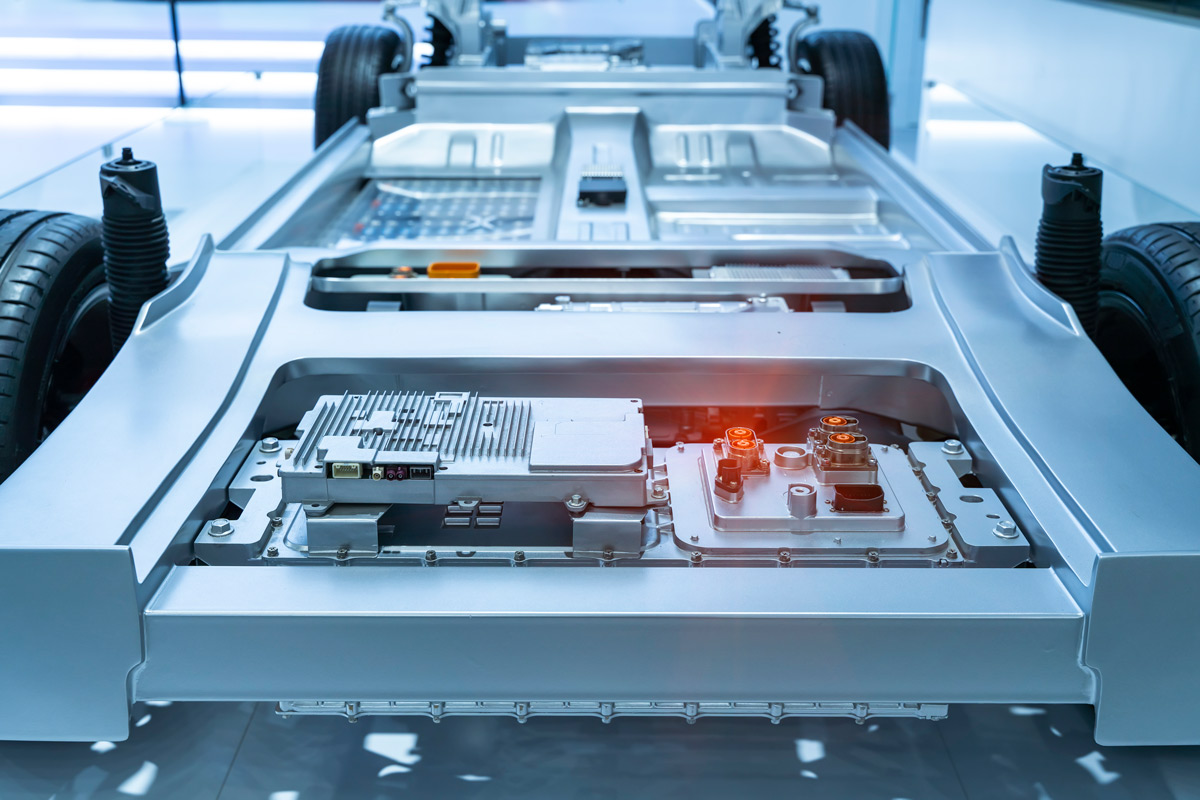

- Battery Module

- Battery Packs (the skateboard)

- Cooling Tubes

- Current Collector

- Cold Plates

- Emotors

- Stators

- Rotors

- Inverters

- Generators

Custom Components for Superior Packaging Performance

We design, engineer and manufacture hundreds of custom compounds and resins with a precise combination of desired properties, including:

- Color

- Wear Resistance

- Flame Retardance

- Impact Strength

- Extrusion

- Durability

- Conductivity

- Temperature Resistance

- Stability

- Chemical Resistance

- Anti-Corrosive

- High Tolerances

We design, engineer and manufacture hundreds of custom compounds and resins with a precise combination of desired properties, including:

- Color

- Wear Resistance

- Flame Retardance

- Impact Strength

- Extrusion

- Durability

- Conductivity

- Temperature Resistance

- Stability

- Chemical Resistance

- Anti-Corrosive

- High Tolerances

“I like to work with PolyFlex. They are indeed pioneers in the plastics industry. Their materials knowledge, design and engineering team and manufacturing experts have helped us meet tight deadlines in the emerging and evolving battery manufacturing industry.”

Give PolyFlex a call early in the design phase of your next battery manufacturing project and immediately put our experience to work for you.