When utilizing robotics to streamline your manufacturing processes, exacting tolerances and consistent levels of repeatability are required. In order to make the most of robotic assistance and to meet these demands, it quickly becomes necessary to employ the use of standardized, high precision in-plant processing trays.

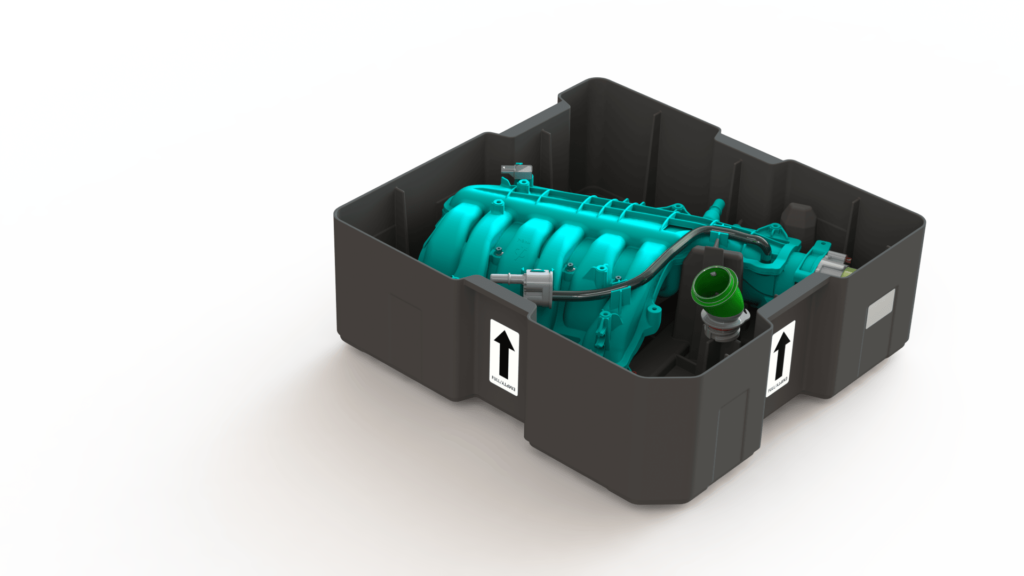

PolyFlex Products offers a range of fully-customizable in-plant processing trays that are created from thermoformed plastic and injection molded inserts. These trays offer the durability needed to survive repeated robotic manipulation as well as the tolerances required to allow them to be transported and accurately held in various positions. Our material-handling experts work directly with our clients to produce custom part presentation pallets and injection-molded trays whose sole purpose is to allow for easy, efficient automation.

As all of our in-plant processing trays are manufactured with injection molded inserts to hold parts firmly in place, they are created with durability in mind. Every tray is guaranteed to withstand repeated use and will hold up to conditions that would – typically – render lesser materials useless. Furthermore, this design ensures that there is less need to replace or repair them, keeping upkeep costs to a minimum.

From flywheel trays and gear wash baskets to fuel rail tote inserts and processing trays, PolyFlex Products has the ability to create a custom in-plant processing tray that can hold up to the rigors of your application. Since our founding, we have been dedicated to offering flexible solutions that provide our clients with optimum value. If you’ve recently implemented robotic assistance into your manufacturing process, or if you’re looking to improve the efficiency of your existing operation, contact one of the experts at PolyFlex Products today. We’ll be happy to examine your situation, offer our opinions and work with you to find an effective, economical solution.