When material handling issues are present it’s not often they can be solved by using thermoformed plastic equipment that has already been designed and manufactured, they often require a custom packaging solution. When you’re transporting parts that are nonstandard, you will likely need a custom storage option or OEM component. In these cases, you should find a material handling manufacturer that uses design services to create a custom packaging solution for your situation.

We use thermoformed plastic, heavy gauge thermoforming, injection molding, and other processes in the design and manufacturing of material handling solutions for our customers. Our trusted team has worked with countless customers to create material handling solutions that meet all requirements and specifications. Once a plan is put together our engineers create a proposal for your review.

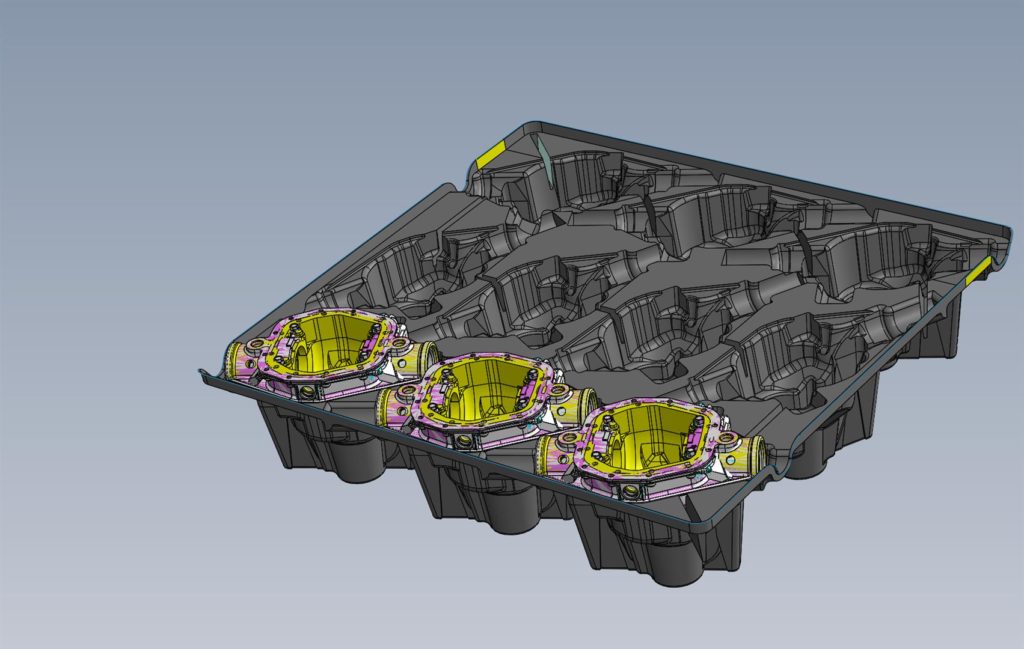

After there is a consensus on the proposal we use out top of the line 3D modeling software and technologies to create prototypes. These tangible model concepts mean you can actually truly visualize the finished product and correct any potential flaws in the design and creation of the prototype. If flaws are discovered, they will corrected by making adjustments in the design phase.

We have design services that include the use of #D modeling, SolidWorks, AutoCAD, and eDrawings. These important resources mean that we can efficiently and effectively move your product from design to prototype. We all know that time is money, so it’s important that your material handling solution is manufactured as quickly as possible.

At PolyFlex, we’re proven and trusted industry leaders in the design, prototyping, and manufacturing of custom material handling solutions through our many design services resources. We have worked with countless industries over the years and are ready and able to handle your custom material handling requests.