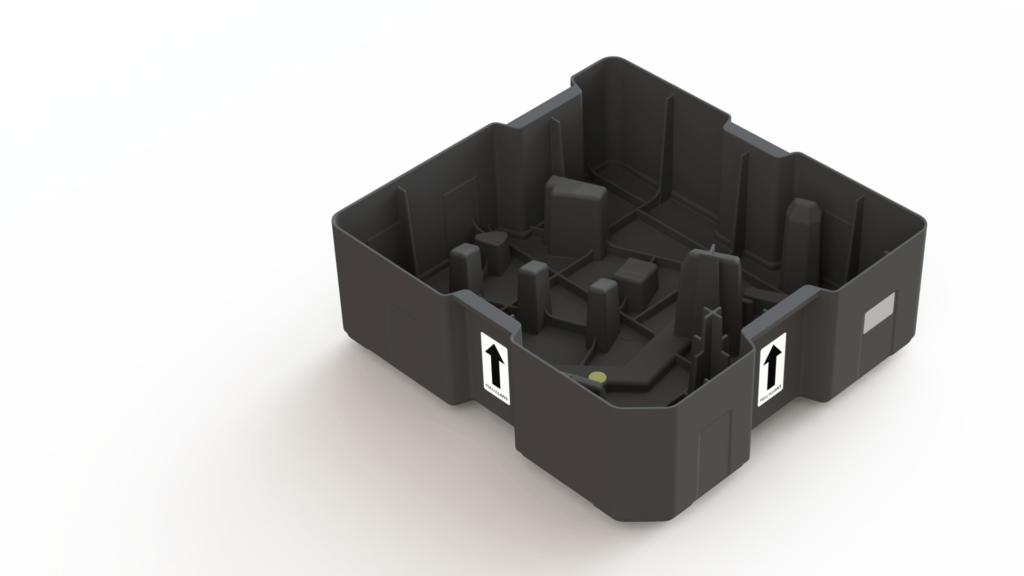

When shipping and handling products that are not as fragile as others, you want a cost-efficient option for thermoformed packaging containers. Our returnable and reusable packaging is a sturdy way to handle important materials, but our in-line thermoforming is the less expensive option to handle less delicate materials you’ve been looking for.

Time is money

We know that when people fill an order, they want it to be ready as soon as possible, and our in-line thermoforming process is the answer. Our in-line thermoformed packaging has a thickness of less than 1.5 mm, meaning it can be fed off a roll rather than sheet fed. What this means for you is a speedy process in terms of feeding, vacuum-forming and trimming your product, reducing the time we need to get your order ready.

A one-time deal

If only a single shipment is something that you need, you don’t want to spend the time and money with one of our reusable or returnable packaging options. Our in-line thermoforming is just as efficient for the one-time use it is designed for. Our in-line thermoformed packaging is also disposable, so once you have gotten your use out of it shipping and handling your products, you can dispose of the package with ease.

You won’t lose quality

Despite the cheaper price tag and smaller thickness, our in-line thermoforming will still give you the quality you can expect from all PolyFlex products. Our process of designing, prototyping, and manufacturing makes sure every thermoformed package is up to your standards and will complete the job you need. In-line thermoformed packaging gives you the value you need in a fast and less expensive way.

PolyFlex delivers excellence with our custom design and manufacture of plastic, urethane, and rubber solutions. If you need thermoformed packaging that will transport your products in a safe and efficient way, contact us today!